This blog is all about the Tamar sailing barge Shamrock. She has been around since 1899 and still going strong.

Saturday, 27 May 2017

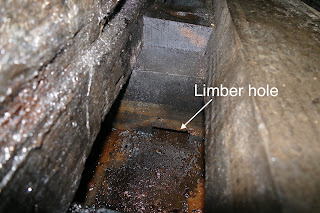

Limber Holes

To enable water to be pumped out of Shamrock the frame floors have draining channels (limber holes) cut out of their under sides, to port and starboard of the centre line, to enable water to flow freely on each side of the keelson to the pump well. Some vessels have a light chain running through the limber holes from forward to aft. These chains, when pulled back and forth occasionally, keep the ’Limber’ holes free of any blockage. Any blockages on Shamrock have to be cleared by hand by the crew. To allow access to the limber holes the thick limber planks are bolted parallel to and 150 mm (6 in) out from the keelson, thus leaving a gap on each side of it. When the hold is empty it is a good policy to leave the gaps uncovered to allow air to circulate and ventilate the frame spaces. Note: due to the number of visitors this is not practical on Shamrock as they would be a hazard. When cargo is to be loaded, the gaps are covered with portable limber boards, which seat on to spacing blocks placed on the frames so that they lie flush with the surface of the limber planks. The thick limber planks, like the Beamshelf, provide extra longitudinal strength within the hull. In Shamrock the planks are of 100 mm (4 in) thick Douglas Fir and just under 254 mm (10 in) wide. Their outer edges are bevelled along their length to match up with the ceiling planks in the bottom of the hold.

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment